I. Introduction

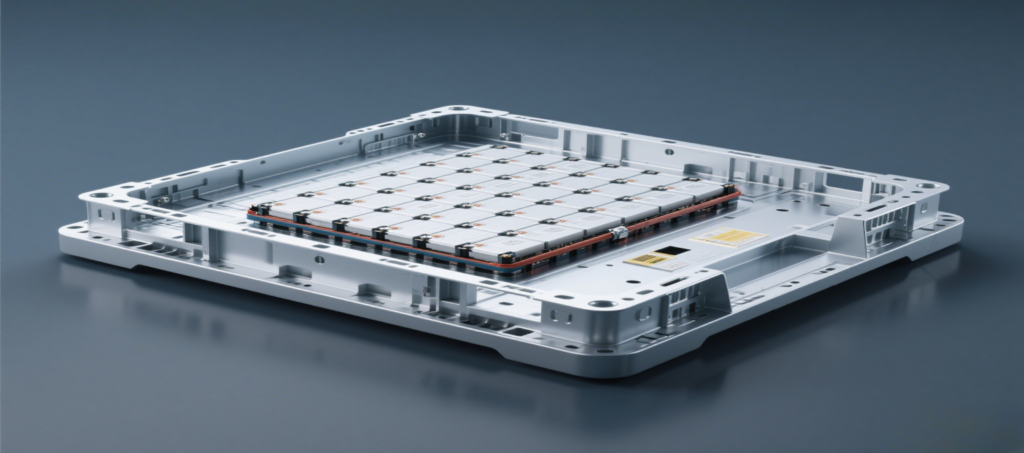

In the wave of the rapid development of the global new energy vehicle (NEV) market, the power battery, as its core component, has become the focus of the industry in terms of safety, lightweight design, and cost control. The battery tray, as the supporting structure of the battery system, has a direct impact on the vehicle’s cruising range, safety, and production efficiency. Currently, aluminum alloy, with its excellent performance, has become the mainstream material for battery trays of new energy vehicles. This article will deeply analyze the core advantages of aluminum alloys and, combined with actual industry cases, explore their competitiveness in the application of battery trays.

II. Core Advantages of Aluminum Alloy Battery Trays

1. Lightweight Design: The Key to Increasing the Cruising Range

Core Advantage: The density of aluminum is approximately 2.7 g/cm³, significantly lower than that of steel (7.8 g/cm³). It enables 30%–50% weight reduction, directly improving the vehicle’s cruising range.

Case Analysis:

Tesla Model 3’s battery tray uses 6000-series aluminum alloys (e.g., 6061 and 6082), achieving 40% weight reduction compared to steel, with a 5%–10% increase in cruising range.

BYD’s “Blade Battery” tray employs high-strength aluminum alloy profiles with extrusion processes, achieving 160 Wh/kg energy density while maintaining structural stiffness.

2. High Strength and Rigidity: A Solid Guarantee for Battery Safety

Technical Highlights: Aluminum alloys (e.g., 6xxx and 7xxx series) optimized via alloy composition and structural design meet collision safety requirements.

Application Cases:

NIO ET7 uses an integrated high-pressure die-cast aluminum tray (AlSi10Mg), increasing torsional stiffness by 30% in side collision tests.

XPeng G9’s tray combines 6-series aluminum alloy with laser welding, achieving 20% higher stiffness and IP68 certification.

3. Corrosion Resistance: Extending Service Life

Performance Advantage: Aluminum alloys form a dense oxide layer (Al₂O₃), offering superior salt spray resistance compared to steel.

Practical Verification:

CATL’s CTP technology uses anodized and coated aluminum trays with >10-year lifespan in harsh environments.

GAC Aion’s magazine battery system employs 6-series aluminum alloy with fluorocarbon coating, passing high-humidity tests in Hainan.

4. Manufacturing Flexibility: Dual Optimization of Cost and Efficiency

Process Advantage: Aluminum alloys support diverse processes (extrusion, die-casting, welding), enabling mass production.

Process Analysis:

Die-Casting: Tesla’s integrated die-cast tray (6000T Giga Press) reduces parts from 70+ to 1, slashing production time from 1–2 hours to 3 minutes and costs by 20%.

Extrusion + FSW: BYD’s Blade Battery combines aluminum profiles with friction stir welding (FSW), achieving base-metal weld strength and zero thermal deformation.

5. Recyclability: Aligning with Sustainability

Environmental Advantage: Aluminum alloys have >90% recycling rates, with far lower carbon emissions than steel.

Data Support:

Recycled aluminum production consumes 5% of primary aluminum’s energy (IAI data). BMW iX3 uses 30% recycled aluminum, reducing emissions by 15 kg/tray.

Zhongwang Group’s closed-loop recycling system supplies low-carbon aluminum to NIO and Li Auto.

III. Analysis of Typical Cases

Case 1: Tesla’s Integrated Die-Cast Aluminum Tray

Material: AlSi10MnMg (high-strength cast aluminum alloy)

Процесс: 6000T Giga Press die-casting

Advantages:

Parts reduced from 70+ to 1, cutting welding defects.

20% cost reduction, 90% faster production, and 30% weight loss (Model Y range +8%).

Case 2: BYD’s Blade Battery Aluminum Alloy Tray

Material: 6061-T6 (extruded aluminum alloy)

Процесс: Multi-cavity extrusion + FSW welding

Advantages:

50% higher stiffness, passing strict safety tests (e.g., nail penetration).

40% lighter than steel, enabling Han EV’s 600+ km range.

IV. Challenges and Future Trends

Despite advantages, aluminum alloys face challenges:

Cost Fluctuations: Price volatility requires scale production (e.g., integrated die-casting).

Process Threshold: High equipment investment for laser welding/FSW.

Material Innovation: Future focus on aluminum matrix composites (e.g., carbon fiber-reinforced aluminum).

V. Conclusion

Aluminum alloys demonstrate five core advantages in NEV battery trays: lightweight design, safety, corrosion resistance, process flexibility, and sustainability. Cases from Tesla and BYD validate their feasibility. With advancements in die-casting and recycling, aluminum alloys will dominate this market, driving NEVs toward greater efficiency and sustainability.