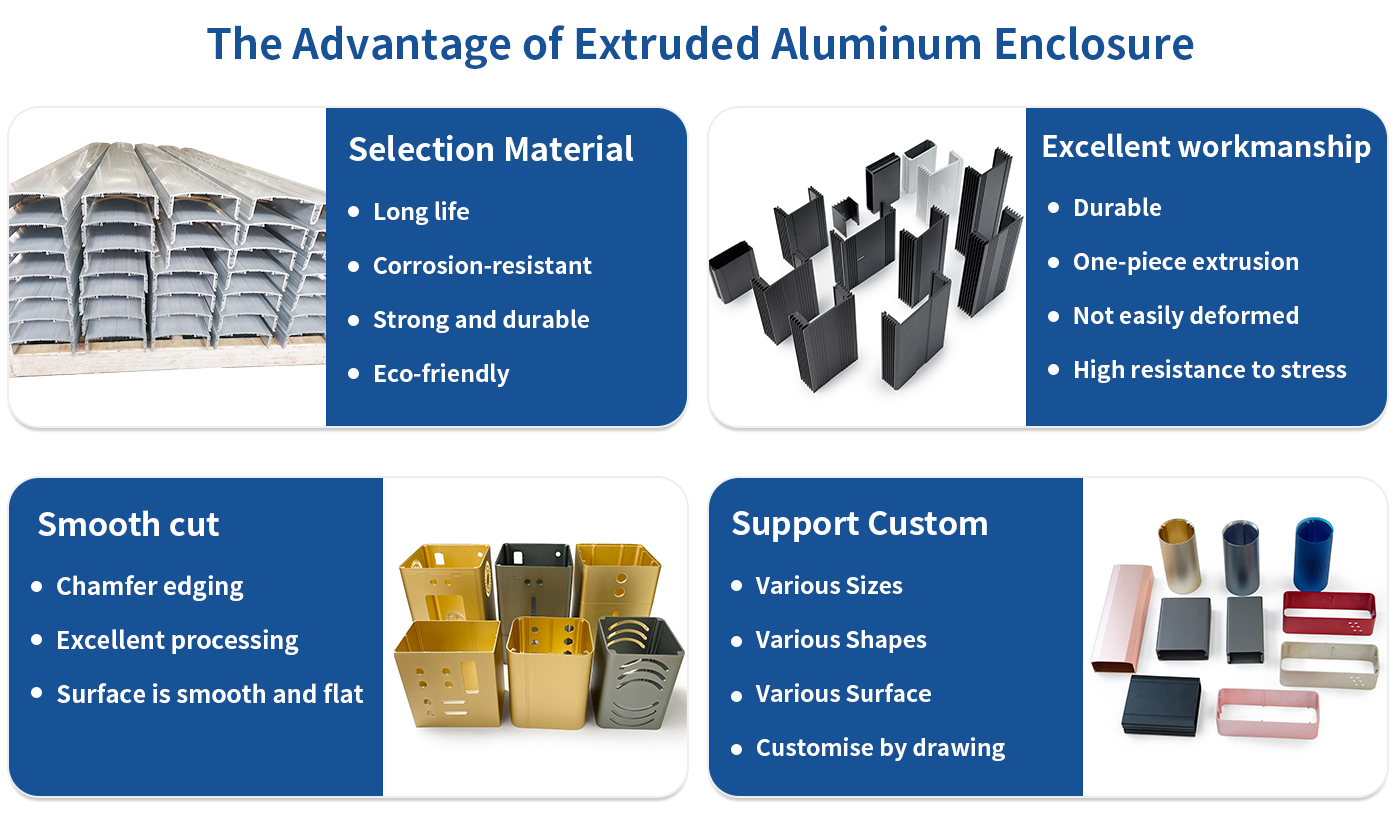

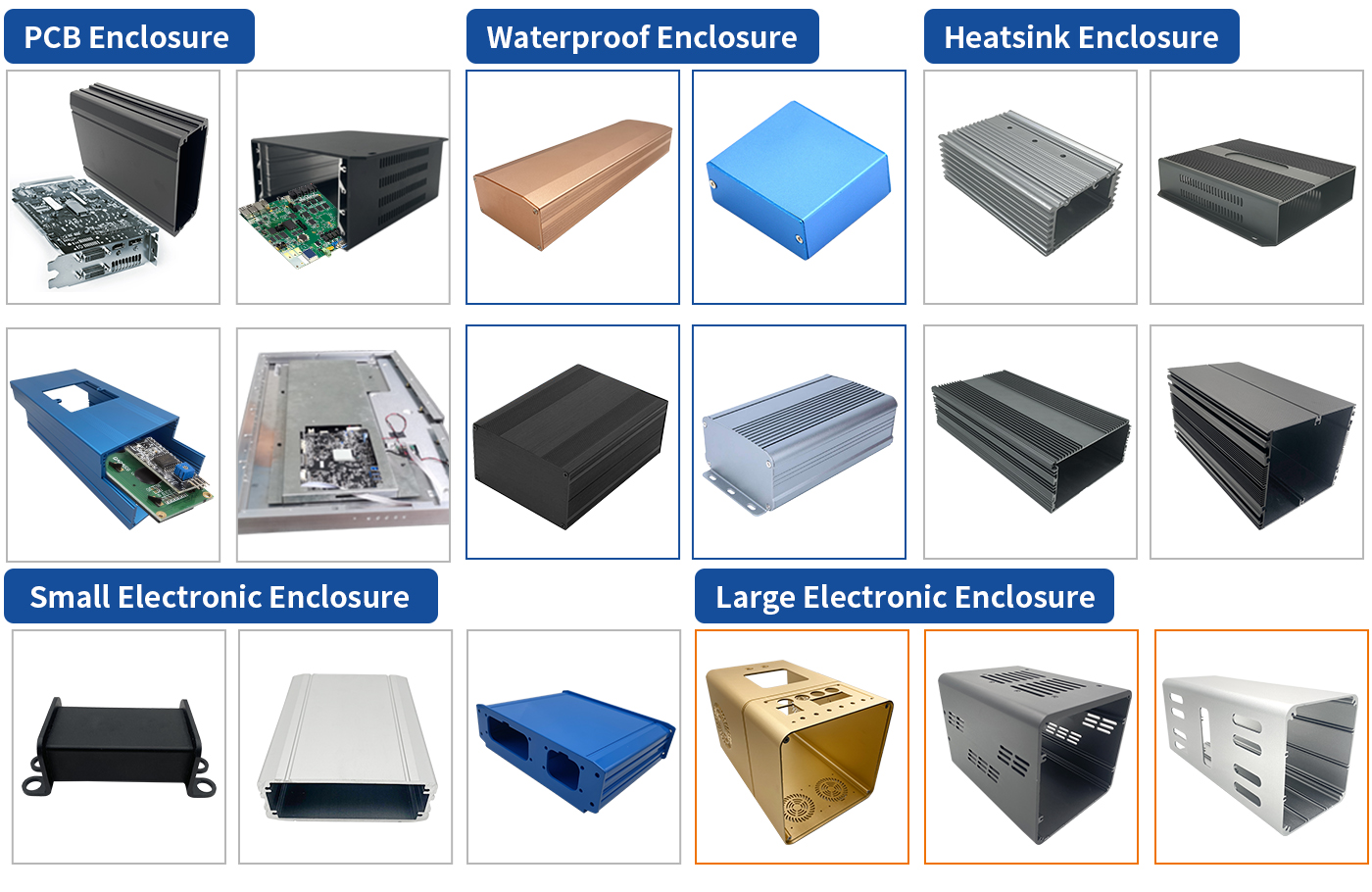

Extruded Aluminum Enclosure

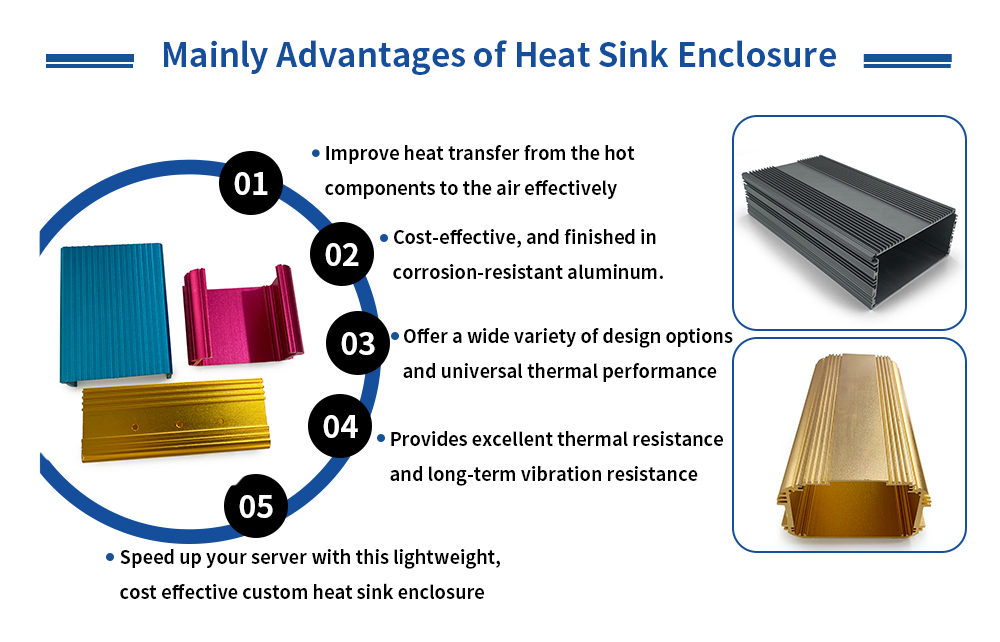

ShangLi extruded aluminum enclosure is here to solve the cooling problem of your projects. We have a team of professional engineers helping you all the way from designing, testing, and manufacturing your high-level extruded aluminum enclosure.Heatell extruded aluminum enclosure uses the best surface treatment. The most common is anodizing.

- Easy and fast prototype lead time

- Conformed with European Rohs guidelines

- Advanced thermal design and management system

- All heatsink products strictly complied with the industry standard

Extruded Aluminum Enclosure Manufacturer Process

Raw material selection

We strictly select high-purity aluminum materials to ensure that each product has excellent strength and lightweight advantages. All aluminum materials undergo strict quality inspection procedures to ensure that their performance meets international standards.

Mold design and production

The manufacturing of each aluminum product is inseparable from precise mold design. Our engineering team uses advanced CAD and 3D software to customize special molds for customers to ensure that the manufactured products meet the design requirements. The molds undergo multiple rounds of testing and adjustments to ensure the final shape and function of the product. We are good at customizing molds and producing according to customer drawings.

Extrusion process

During the extrusion stage, the aluminum is heated at high temperature, softened and passed through a precision mold under high pressure. This process ensures the complex structure, precise size and density of the material. Through extrusion, we are able to produce aluminum profiles with complex cross-sections and achieve a perfect combination of high strength and high precision.

Processing and Forming

The aluminum is milled, punched, tapped and other processes by high-precision CNC machine tools to give the product high-precision dimensions and complex structures, with a tolerance of no more than 0.02mm. Our equipment can achieve efficient production and meet large-scale customization needs.

Surface treatment

In order to enhance the corrosion resistance and aesthetics of the product, we use a variety of surface treatment processes such as anodizing, spraying, and painting. Anodizing not only improves the hardness of the aluminum surface, but also gives the product an elegant appearance, durable and easy to clean. We can control the color difference of anodizing within 5%.

Laser engraving process

Laser engraving is used to engrave high-precision patterns and text on the aluminum surface. This process not only ensures the clarity and durability of the logo, but also enhances the aesthetics and brand value of the product.

Silk screen printing process

Silk screen printing is used to print patterns, logos and information on the surface of aluminum products. Through high-quality silk screen printing, we can achieve bright and long-lasting printing effects to ensure that the product logo is clearly visible.

Quality Inspection

We have a group of highly qualified production staff who are trained weekly on product quality awareness and production processes. Skilled operation and strict quality awareness ensure that every product and every process can be completed to high standards. Each aluminum product undergoes strict quality inspection before leaving the factory, including hardness test, tensile strength test, surface finish and color difference inspection, etc., to ensure superior product performance and long service life.

Oxidation Production Line

Long Profile Oxidation

Production Line

Short Profile Pxidation

Production Line

Polishing

Production Line

Sand Blasting

Production Line

Process Flow

.jpg)