Surface Treatment Team

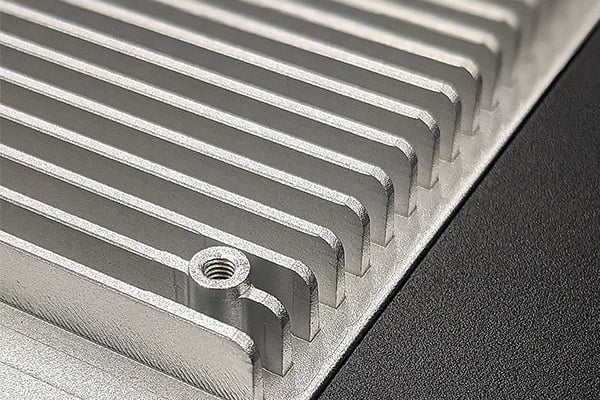

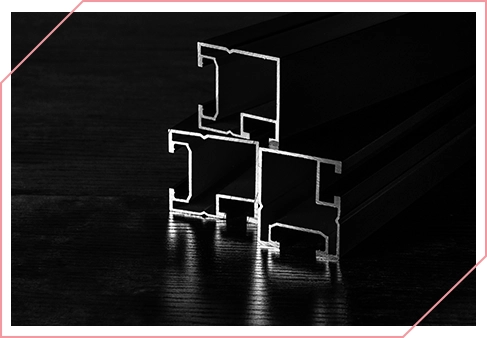

At our company, high-quality surface treatments are a testament to the expertise and pursuit of perfection of our professional team. We have several oxidation treatment plants located in Sanshui District, Foshan City, China, and we have extensive knowledge in this field and are committed to improving the quality and performance of aluminum profiles.

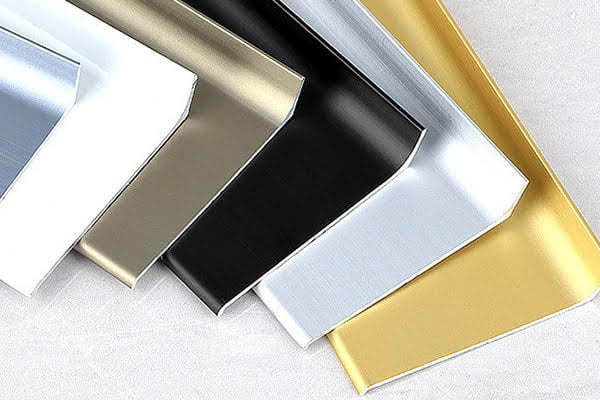

Our team specializes in a variety of surface treatment methods, including sophisticated anodizing processes that create a corrosion-resistant oxide layer, and innovative technologies such as electrophoretic coatings that achieve a uniform, corrosion-resistant finish. We can also provide precise powder coating, providing vibrant colors and durable finishes.

Committed to both beauty and functionality, our surface treatment team uses sandblasting for texture variations and applies expertise at every step to ensure aluminum profiles meet and exceed industry standards. Trust our team to enhance your project with superior surfacing solutions.