In the dynamic landscape of industrial manufacturing, custom extruded aluminum enclosures have emerged as a cornerstone for protecting sensitive electronics, streamlining equipment design, and enabling innovation across industries. From aerospace to consumer electronics, these enclosures offer unmatched versatility, durability, and thermal performance. In this blog, we’ll explore what makes extruded aluminum enclosures a game-changer, their design potential, and how they solve real-world engineering challenges.

What Are Extruded Aluminum Enclosures?

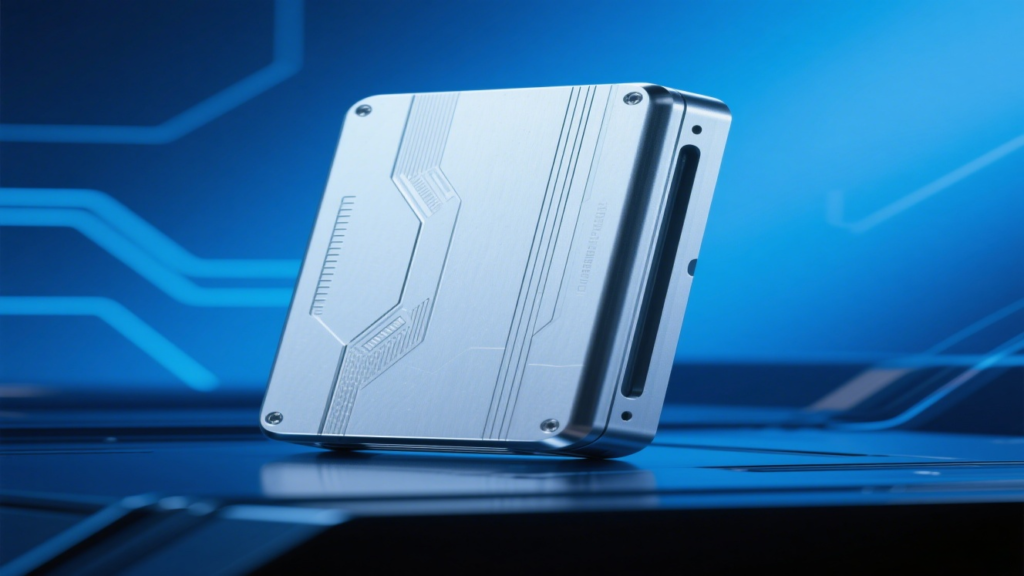

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create uniform cross-sectional shapes. When customized for enclosures, this process produces lightweight, high-strength housings tailored to specific dimensions, features (like heatsinks, mounting rails, or ports), and aesthetic requirements.

Unlike off-the-shelf plastic or metal boxes, custom extruded aluminum enclosures are built to:

- Fit unique electronic layouts (e.g., PCBs, sensors, wiring).

- Withstand harsh environments (temperature, moisture, corrosion).

- Optimize thermal management (critical for power-hungry devices).

Why Choose Custom Extruded Aluminum?

1. Unbeatable Thermal Performance

Aluminum’s thermal conductivity (≈205 W/m·K) is far superior to plastics (e.g., ABS at ~0.2 W/m·K) or steel. For devices like power amplifiers, LED drivers, or industrial controls, extruded aluminum enclosures act as passive heatsinks—dissipating heat without fans, reducing noise, and improving reliability.

Example: A custom amplifier enclosure with finned extrusions can reduce component temperatures by 20–30°C, extending lifespan and preventing thermal throttling.

2. Lightweight & Durable

Aluminum alloys (e.g., 6061, 6063) offer a perfect balance of strength and weight. Compared to steel, aluminum enclosures are:

- 3x lighter (ideal for portable or aerospace applications).

- Resistant to corrosion (even in outdoor or marine environments with anodizing).

- Capable of withstanding mechanical stress (vibration, impact) without deforming.

3. Design Flexibility

With extrusion, your enclosure isn’t limited to standard shapes. Engineers can:

- Integrate heatsinks, flanges, or mounting brackets directly into the design.

- Add custom cutouts for connectors, displays, or ventilation.

- Anodize or powder-coat for color, UV resistance, or extra corrosion protection.

This flexibility means enclosures can be tailored to match brand aesthetics or fit seamlessly into existing systems.

4. Cost-Effective for Medium-to-Large Volumes

While tooling costs for custom extrusion dies exist, the process becomes highly economical at scale. For industries like automotive (EV chargers), telecommunications (5G equipment), or medical devices, the long-term savings (from reduced assembly, thermal management, and maintenance) outweigh initial investments.

Applications Across Industries

1. Electronics & Telecom

- 5G Infrastructure: Enclosures protect outdoor antennas and routers, with extruded fins managing heat in remote locations.

- Audio Equipment: Custom amp enclosures enhance sound quality by minimizing electrical interference and cooling components.

2. Industrial & Automation

- Control Panels: Rugged enclosures shield PLCs and sensors from dust, moisture, and mechanical shock on factory floors.

- Renewable Energy: Solar inverters and battery management systems use aluminum enclosures for thermal efficiency and weather resistance.

3. Medical Devices

- Portable Diagnostics: Lightweight, sterilizable enclosures house sensitive imaging or testing equipment for clinics and field use.

4. Consumer Goods

- Smart Home Tech: Sleek, anodized enclosures for IoT hubs or smart speakers blend functionality with modern design.

Designing Your Custom Enclosure: Key Considerations

- Function First: Define requirements like:

- Operating environment (temperature, IP rating).

- Thermal load (Wattage of components).

- Mounting/installation needs (wall, rack, or portable).

- Collaborate with Experts: Partner with a manufacturer who offers end-to-end services (design, prototyping, extrusion, finishing). They’ll help optimize wall thickness, ribbing for strength, and heatsink geometry.

- Finishing Touches: Anodizing (Type II or III) adds corrosion resistance and color. Powder coating offers endless aesthetic options.

Case Study: Custom Enclosure for a High-Power LED Driver

A client needed an enclosure for a 500W LED driver used in industrial lighting. Key challenges:

- Dissipate 150W of heat passively.

- Withstand outdoor UV exposure and moisture.

- Fit into a compact 1U rack-mount system.

Solution: A custom extruded aluminum enclosure with integrated heatsink fins, an IP66-rated seal, and anodized black finish. The design reduced component temperature by 25°C, eliminated fan noise, and met rugged environmental standards.

The Future of Extruded Aluminum Enclosures

As industries push for smaller, more powerful, and sustainable devices, aluminum enclosures will play a bigger role:

- Miniaturization: Extrusion allows precise, compact designs for wearables and IoT devices.

- Sustainability: Aluminum is 100% recyclable, aligning with eco-friendly manufacturing trends.

- Advanced Alloys: New composites (e.g., aluminum with graphene) will boost thermal performance further.

Final Thoughts

Custom extruded aluminum enclosures aren’t just “boxes”—they’re engineered solutions that protect, cool, and elevate your products. Whether you’re designing the next industrial control system or a consumer gadget, their blend of performance, flexibility, and cost-effectiveness makes them indispensable.

Ready to bring your enclosure idea to life? Partner with a manufacturer that specializes in custom extrusion—your design, their expertise, and a product built to last.

Got questions about extrusion design or applications? Drop a comment below, or reach out to our team for a free consultation!