Amid rapid technological advancements, electronic devices have flooded into every aspect of human life. From everyday smartphones and tablets to specialized industrial control systems and servers, these devices are ubiquitous. Behind their functionality lies a critical component: extruded aluminum electronic enclosures. These enclosures not only provide robust protection but also enhance the aesthetic appeal of devices.

I. Extruded Aluminum Process: Crafting Durable Enclosures

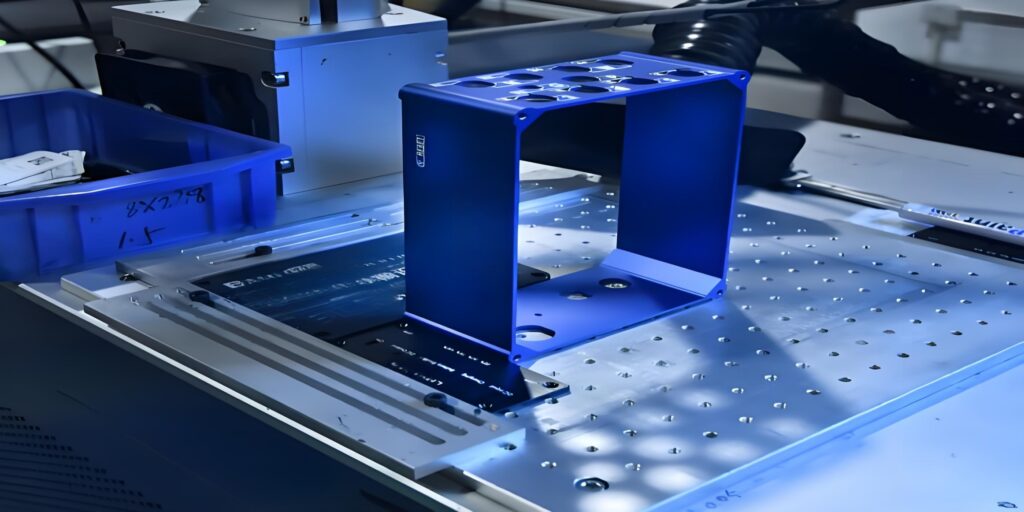

The production of extruded aluminum electronic enclosures relies on advanced aluminum extrusion technology. This process uses aluminum or aluminum alloy as raw material. Heated aluminum billets are placed into an extrusion machine, where immense pressure forces the material through a shaped die to create profiles with specific cross-sectional geometries. Compared to other manufacturing methods, aluminum extrusion offers distinct advantages:

- It enables the production of complex, high-precision profiles to meet diverse design requirements for electronic enclosures.

- The resulting aluminum profiles exhibit superior mechanical properties, including enhanced strength, hardness, and toughness, ensuring reliable protection for electronic components.

After extrusion, secondary processing steps—such as cutting, drilling, tapping, and surface treatment—transform the aluminum profiles into finished enclosures. Cutting ensures proper dimensions, while drilling and tapping create holes for screws and connectors. Surface treatments are critical:

- Anodizing forms a hard, corrosion-resistant oxide layer, improving durability and aesthetics.

- Painting adds color and personalization.

- Sandblasting creates a textured finish for improved grip and visual appeal.

II. Key Advantages of Extruded Aluminum Enclosures

- Exceptional Thermal Management

Electronic devices generate significant heat during operation. Extruded aluminum enclosures excel at conducting heat away from internal components and dissipating it through convection, ensuring stable performance—a critical feature for high-performance computers and gaming systems. - Effective Electromagnetic Shielding

With rising electromagnetic interference (EMI) concerns, aluminum enclosures act as barriers against internal and external EMI. This is vital for communication equipment, medical devices, and other EMI-sensitive applications. - Lightweight Yet High-Strength Design

Aluminum’s low density allows extruded enclosures to achieve lightweight designs without compromising strength. This balance supports portability in consumer electronics and meets durability demands in industrial settings.

III. Diverse Applications

Extruded aluminum enclosures are widely adopted across industries:

- Consumer Electronics: Smartphones, tablets, and laptops leverage their sleek aesthetics and durability.

- Industrial Control: Control panels and machinery enclosures rely on their corrosion resistance and EMI shielding for harsh environments.

- Automotive & Aerospace: Used in dashboards, displays, satellites, and aircraft, where lightweight and high-performance materials are essential.

IV. Challenges and Opportunities

While extruded aluminum enclosures dominate the electronics industry, challenges persist:

- Cost Efficiency: Manufacturers must optimize processes and materials to remain competitive.

- Innovation Demands: Evolving consumer expectations for performance and design require continuous R&D investment.

Opportunities, however, abound:

- Emerging Technologies: 5G, AI, and IoT drive demand for advanced electronic devices, expanding the market for aluminum enclosures.

- Sustainability: Eco-friendly production methods and recyclable materials align with global environmental trends.

Conclusion

Extruded aluminum electronic enclosures play a pivotal role in modern electronics, blending functionality with design. As technology evolves, this industry will continue to innovate, supporting the growth of next-generation devices while embracing sustainability and efficiency.