Why is Heat Dissipation the Lifeline of LED Drivers?

In the world of LED lighting, heat management determines performance, stability, and lifespan. Unlike traditional light sources, LED drivers are highly sensitive to heat. When an LED driver overheats, several problems can occur:

Reduced Efficiency: Excessive heat lowers conversion efficiency, leading to wasted energy.

Shortened Lifespan: Heat stress accelerates component aging, causing premature driver failure.

Color Deviation: High temperatures can cause LEDs to shift in color or brightness, reducing lighting quality.

Safety Hazards: Overheating increases the risk of short circuits, system breakdowns, and fire hazards in extreme cases.

Research shows that for every 10°C increase in operating temperature, the lifespan of an LED driver can be reduced by nearly 50%. This makes heat dissipation the true “lifeline” of LED drivers.

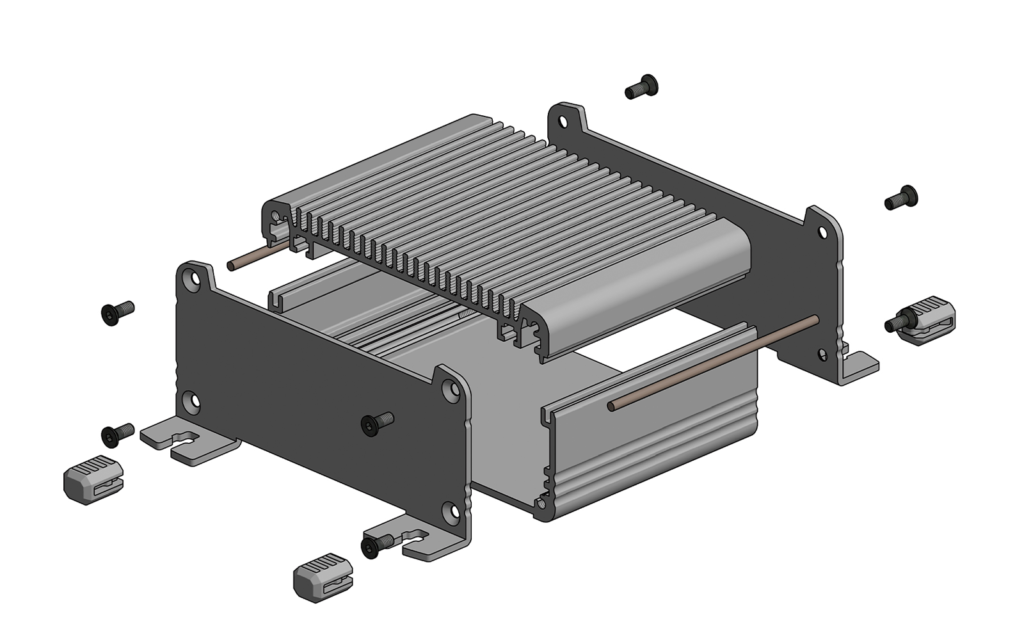

That’s where heat-sinking aluminum enclosures come in. They not only provide mechanical protection but also function as efficient thermal conductors, keeping LED drivers cool and stable.

Aluminum: The “Infallible Choice” for Heat-Sinking Enclosures

When it comes to thermal solutions, aluminum stands out as the material of choice. Here’s why:

1. Excellent Heat Dissipation

Aluminum has high thermal conductivity (typically around 200 W/mK), allowing it to quickly transfer heat away from the LED driver. Compared to plastic or steel enclosures, aluminum ensures far superior cooling efficiency.

2. Excellent Heat Resistance

When exposed to high temperatures, aluminum naturally forms an oxide layer on its surface. This layer prevents further oxidation and discoloration, enabling the enclosure to maintain both performance and appearance over time.

3. Excellent Ductility

Aluminum is lightweight yet ductile, which means it can be easily processed into different designs and complex shapes. Whether you need fin structures for maximum cooling or slim enclosures for compact designs, aluminum allows for a wide variety of styles without losing strength.

4. Lightweight but Durable

Aluminum enclosures are much lighter than steel alternatives but still provide robust structural protection. This makes them especially suitable for LED lighting systems that require easy installation and long-term reliability.

With these properties, aluminum is not just a practical choice—it’s the infallible choice for heat-sinking enclosures in the LED lighting industry.

What Qualities Should an Excellent Heat-Sinking Aluminum Enclosure Possess?

Not all aluminum enclosures are created equal. To ensure optimal performance, a high-quality aluminum heat sink enclosure should have the following features:

1. Optimized Heat Sink Design

Dense fin structures to maximize surface area for heat dissipation.

Proper airflow channels for both natural and forced convection.

Customized geometry to match the power and size of the LED driver.

2. Surface Treatment for Durability

Anodized coatings enhance corrosion resistance and thermal stability.

Surface finishing also prevents scratches and discoloration, ensuring the enclosure maintains a professional appearance.

3. Mechanical Strength & Safety

Adequate wall thickness to resist deformation.

High impact resistance for use in outdoor or industrial environments.

Compliance with safety standards for electrical insulation and fire resistance.

4. Design Flexibility

Customizable dimensions and shapes to match different driver sizes.

Compatibility with mounting options, connectors, and cabling needs.

Options for waterproof and dustproof sealing to meet IP-rated enclosures for outdoor lighting.

5. Aesthetic & Functional Balance

For LED lighting in architectural and commercial spaces, appearance matters. An excellent heat-sinking aluminum enclosure not only performs but also complements the product design.

How to Choose the Right Aluminum Enclosure for Your Driver?

Choosing the right aluminum heat sink enclosure is not only about material—it’s about finding the right balance between performance, cost, and application needs. Consider these key factors:

1. Power Rating of the LED Driver

Low-power drivers may only require basic aluminum enclosures with simple heat dissipation.

High-power drivers (e.g., for streetlights, stadium lighting) need advanced enclosures with large fins, forced cooling support, or custom heat pipe integration.

2. Operating Environment

Indoor lighting: Focus on aesthetics and moderate heat dissipation.

Outdoor or industrial lighting: Prioritize IP65/IP67 protection, corrosion resistance, and high durability.

3. Enclosure Size & Fit

Choose enclosures that provide enough internal space for PCB boards and wiring, but without excessive volume that wastes material.

A compact yet efficient heat sink design ensures optimal thermal management.

4. Customization Options

For manufacturers, working with a supplier that offers CNC machining, extrusion, and anodizing customization ensures you get a tailor-made solution instead of a one-size-fits-all design.

5. Cost vs. Performance Balance

While higher-end enclosures may have advanced thermal features, not all applications require maximum performance. Work with your supplier to match product performance with budget.

Our Solutions and Product Advantages

At ShangliEnclosure, we specialize in the design, production, and manufacturing of aluminum enclosures and heat sink solutions for the LED lighting industry. Our products are built to solve real-world challenges of LED driver manufacturers.

Here’s why our aluminum enclosures are trusted by clients worldwide:

1. High-Efficiency Heat Dissipation

Our extruded aluminum heat sink enclosures are engineered with dense fin designs that deliver superior cooling performance, keeping LED drivers stable even in demanding environments.

2. CNC Precision Machining

Using advanced CNC processing, we provide accurate dimensions and complex structures to meet any custom requirement, ensuring perfect fit and finish.

3. Surface Treatment Excellence

We offer anodizing, sandblasting, and powder coating, giving our enclosures both excellent heat resistance and long-term durability.

4. Wide Range of Customization

From compact enclosures for residential LED drivers to heavy-duty housings for industrial lighting, we provide flexible customization options—size, shape, and finishing tailored to your needs.

5. Reliability & Cost-Effectiveness

Our aluminum enclosures combine premium quality with competitive pricing, ensuring the best balance of performance and affordability.

6. Industry Applications

Street lighting LED drivers

Commercial & architectural lighting

Industrial high-bay lighting

Smart city lighting systems

Outdoor waterproof LED drivers

By choosing our aluminum heat sink enclosures, you ensure your LED drivers remain cool, reliable, and long-lasting—directly enhancing the value of your lighting solutions.