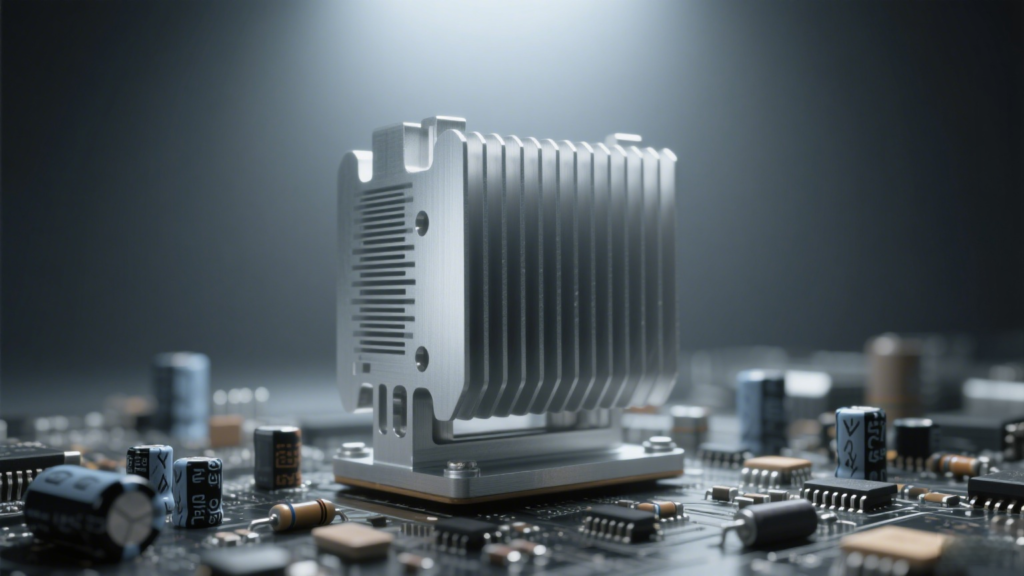

In the realm of thermal management, aluminum heatsinks stand as unsung heroes. They quietly ensure electronic devices and systems stay cool, enabling peak performance. Today, we dive deep into this diverse world of cooling champions — from standard heat sinks to specialized designs like the Automotive aluminum alloy heatsink and beyond.

The Basics: Why Aluminum Heatsinks Matter

Aluminum, prized for its excellent thermal conductivity and cost – effectiveness, is the go – to material for heatsinks. A typical heat sink absorbs and dissipates heat from components like CPUs or power transistors. Whether it’s a simple round aluminum heat sink for small electronics or a complex High density aluminum alloy heatsink for industrial use, the goal is the same: keep things cool to avoid performance issues and component failure.

Diverse Designs for Every Need

The world of aluminum heatsinks is remarkably varied:

- Sunflowers heat dissipation fin: Its unique structure boosts surface area, much like sunflower petals maximize sunlight absorption, enabling more efficient heat dissipation.

- Automotive aluminum alloy heatsink: Built to endure a vehicle’s harsh engine bay, it manages heat from components like power inverters and ignition systems.

- Aluminum extrusion chassis: Serves dual purposes — structural support and acting as a heatsink to manage enclosure heat.

- Nvme enclosure & enclosure speaker setups: Rely on compact, efficient aluminum heatsinks to prevent overheating during prolonged use.

Specialized & Custom Solutions

For high – performance demands:

- Hi power aluminum heat sink: Engineered to handle extreme heat loads in industrial machinery or high – end electronics.

- Customized extruded aluminum alloy heatsinks: Gaining popularity, as they’re tailored to fit unique device geometries and thermal needs.

Gaming enthusiasts know the asus z790 formula heatsink — a prime example of how aluminum heatsinks integrate into motherboards to cool CPUs during intense gaming. Meanwhile, the rackmount heatsink is a data center staple, ensuring servers stay within optimal temps.

Beyond Electronics: Heatsinks in Other Fields

Aluminum heatsinks aren’t just for electronics:

- Aluminum shell power case: Combines protection and thermal management to keep power supplies stable.

- Aluminum alloy heat sink LED: In lighting, this design ensures heat – sensitive LEDs have reliable cooling, prolonging lifespan and brightness.

Types of Aluminum Heatsink Structures

Structural designs vary too:

- Integrated aluminum alloy heatsink: Simplifies assembly by combining components into one cooling unit.

- F – type aluminum alloy heatsink: Balances surface area and space efficiency.

- 8050 aluminum alloy heatsink: A specific model favored for dimensions and thermal performance in certain apps.

- Heatsink junction box: Cleverly integrates heat management with safe electrical connection housing.

In conclusion, aluminum heatsinks are the backbone of thermal management across industries. From simple consumer gadget heat sinks to complex industrial Customized extruded aluminum alloy heatsinks, they ensure tech runs smoothly. As devices grow more powerful and compact, their role becomes even more vital — a silent, essential force in tech.

Next time you power up a device, listen to a speaker, or drive your car, remember the humble aluminum heatsink working behind the scenes. Here’s to these unsung heroes — long live the heatsink!