In a highly competitive materials market, aluminum enclosures have emerged as a leader, securing a dominant position through a combination of unique advantages that outperform rival materials.

1. Superior Thermal Performance

Aluminum excels in heat dissipation, a critical requirement for modern electronics. Devices like computer chips and communication base stations generate substantial heat during operation. Compared to low-thermal-conductivity materials like plastic, aluminum efficiently transfers internal heat to the enclosure surface and dissipates it into the environment. For instance, aluminum PC cases effectively lower CPU and GPU temperatures, ensuring stable performance, while plastic enclosures risk heat buildup, compromising device efficiency and lifespan. This thermal advantage makes aluminum enclosures the go-to choice for high-heat applications in electronics and industrial equipment.

2. Strength and Durability

Despite its lightweight nature, aluminum offers robust mechanical protection. Compared to brittle materials like glass, aluminum enclosures resist impact, deformation, and daily wear. Unlike ordinary steel, aluminum maintains strength while boasting superior corrosion resistance. In harsh environments (e.g., humidity, acids, or alkalis), aluminum naturally forms a dense oxide layer, preventing further corrosion. Outdoor lighting fixtures and surveillance cameras with aluminum enclosures, for example, withstand years of weathering without rust or degradation, unlike enclosures made from less durable materials.

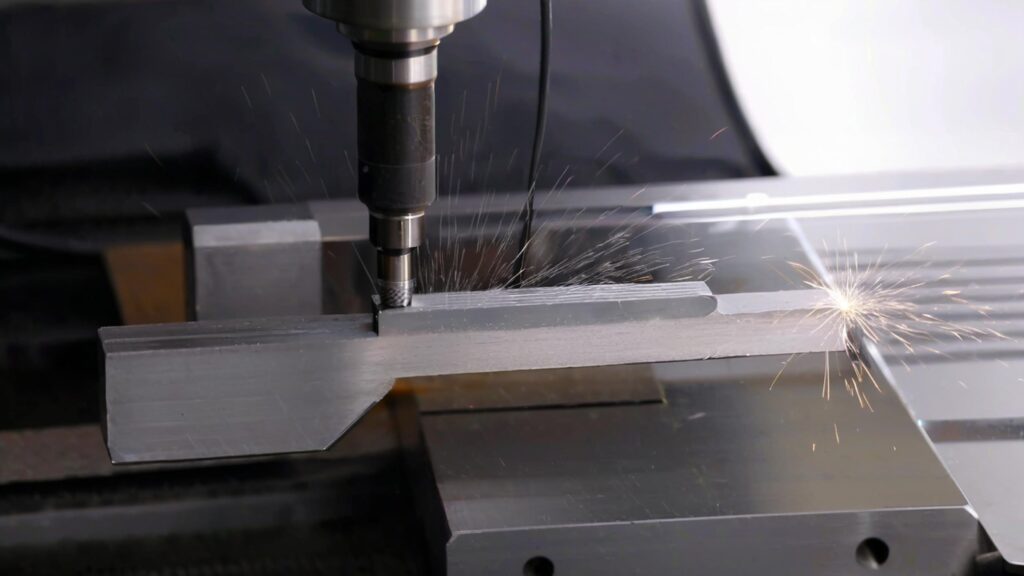

3. Versatile Machinability

Aluminum is highly workable, supporting processes like cutting, drilling, stamping, and bending to create complex shapes. From sleek smartwatch enclosures to large industrial control cabinets, aluminum enables precise, efficient manufacturing with consistent quality. In contrast, ceramics are difficult and costly to machine, limiting their scalability, while natural materials like wood lack the strength, waterproofing, and longevity of aluminum enclosures.

4. Aesthetic Flexibility

Aluminum enclosures combine metallic luster with design versatility. Surface treatments like anodizing, sandblasting, or brushing produce diverse colors and textures, elevating product aesthetics. This adaptability suits both minimalist consumer electronics and rugged industrial equipment, whereas materials like rubber offer limited visual appeal, failing to meet modern demands for style and personalization.

5. Sustainability and Recyclability

As environmental awareness grows, aluminum’s recyclability becomes a key competitive edge. Aluminum enclosures can be efficiently recycled post-use, reducing resource consumption and pollution. This aligns with global sustainability goals, particularly in eco-conscious industries and regions, further solidifying aluminum’s market dominance.

Conclusion

Aluminum enclosures dominate the market by integrating unmatched thermal management, durability, machinability, design versatility, and eco-friendliness. These advantages drive their widespread adoption across electronics, industrial systems, consumer products, and beyond, cementing aluminum as the material of choice for modern engineering challenges.