How To Submit Custom Requirements?

To Ensure That Your Custom Case Meets Your Expectations Perfectly, We Recommend Following This Process:

Provide Basic Information: Inform us of your budget and general requirements.

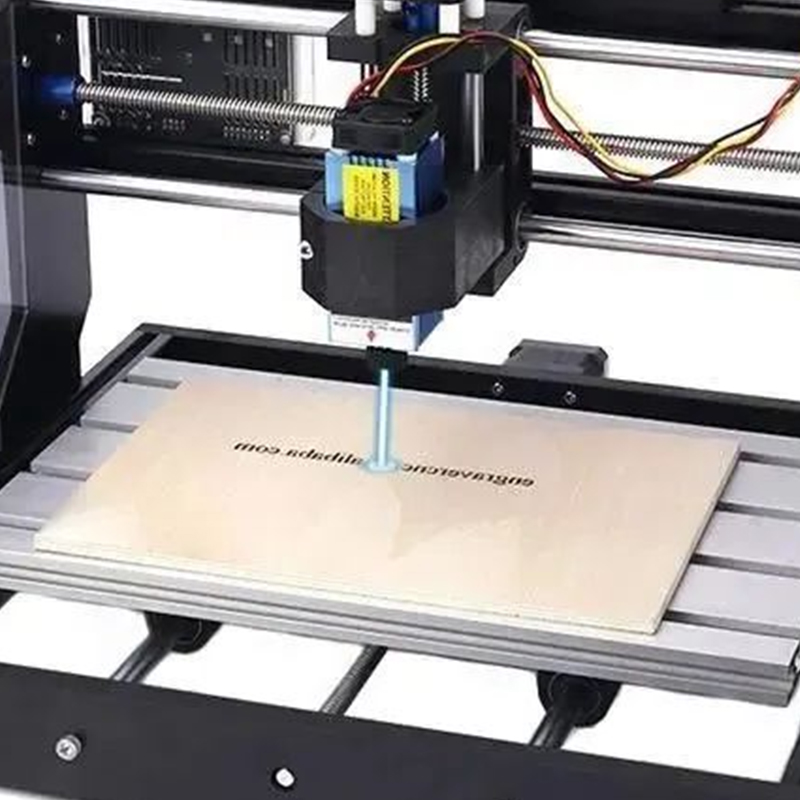

Provide Technical Files: It is best to provide the CAD drawings (such as STEP or IGES format) or detailed size sketches of the case.

Confirm Options: Refer to the above options to clarify your material, process, color, etc., requirements.

Obtain Quotation And Sample: We will provide a quotation based on your needs and arrange for a sample production. Once the sample is confirmed to be correct, mass production can proceed.